Ever wondered what is the semiconductor manufacturing process?

What are the steps involved and what are the machines required?

Here’s an explanation!

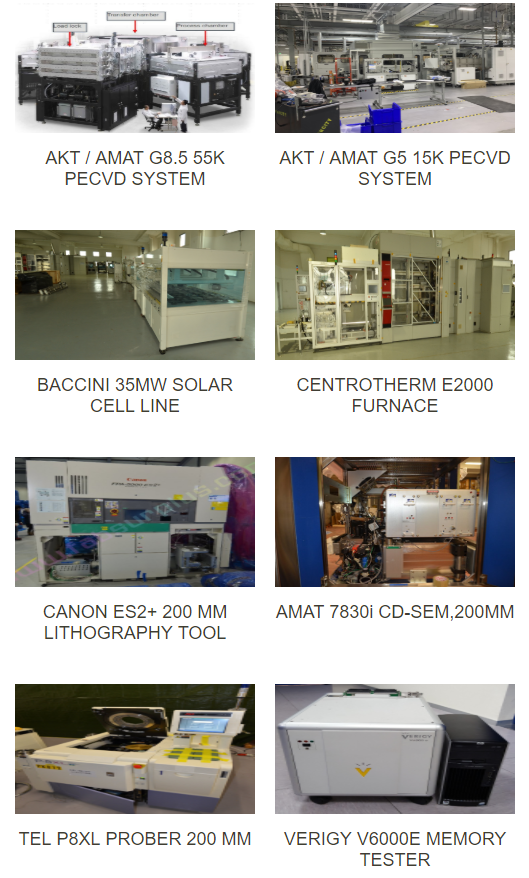

The Semiconductor production process consists of the Front End, in which circuits are placed on silicon wafers, and the Back End, which involves assembly and packaging. SDI Fabsurplus.com equipment for sale covers all aspects of this process.

Points 1 to 10 of the Workflow below belong to the Front End semiconductor process.

Semiconductor manufacturing process flow

Let’s go into detail into most of the processes outlined above.

Oxidation formation

Wafers are placed into a rapid thermal processing system and heated to approximately 1000° Celsius. By exposing wafers to a flow of gas, various films , the oxidation, are created on the wafer surface.

View Rapid Thermal Processing Systems for sale

Photoresist Coating

While the wafers are rotated at a high speed in a coater, they are covered by a uniform coat of photoresist. The resist characteristics change when exposed to ultraviolet light thus, placing an image on the wafer.

View Coaters/Developers for sale

Mask Alignment Exposure

After glass masks with integrated circuit (IC) patterns are aligned with the wafers, ultraviolet (UV) liht is applied to transfer the patterns to the photoresist using a stepper.

View Steppers, Scanners and Photolithography Equipment for sale

Develop

In a developer, the wafers are uniformly covered with a developing solution to develop the mask patterns. With positive photoresist, the portion that has been exposed to light becomes soluble, leaving the mask patterns on the wafer surfaces.

View Coaters/Developers for sale

Etching

A plasma dry etch system is used to strip the dielectric films in accordance with the patterns developed on the photoresist. The portion protected by the photoresist remains intact, preserving the original film structure under the resist

View Dry Etch equipment for sale

Ion Implantation

Ion implantation dopes or implants the surface of the wafer with a known quantity of impurities, such as boron and arsenic. These elements are then shot into the wafer in a bullet-like fashion. Sacrificial films exist, preventing ions from being implanted in unwanted areas of the wafer. Subsequent annealing will diffuse these impurities to a more uniform density.

Interconnect Dielectric Film Deposition

Films are deposited to insulate the devices (transistors) and wires. The deposition technique may use a CVD (Chemical Vapor Deposition) system that accumulates gaseous materials through chemical reactions or an SOD (Spin-on Dielectric) coater that applies liquid material through spinning.

View Photoresist Coat and Development equipment for sale

Metal Deposision / Etching

After the inter-layer dielectric (ILD) films are etched, a CVD (Chemical Vapor Deposition) or PVD (Physical Vapor Deposition) system is used to deposit metal films to form wiring.

View PVD equipment for sale

View CVD equipment for sale

Wafer Test

Each completed wafer contains hundred of identical ICs. A wafer prober and a tester work together to inspect these individual ICs . Results of these tests determine “good” and “bad” ICs.

View Testers for sale

Assembly Process : Dicing

Following wafer test, the ICs on the wafer are cut into IC chips several square-millimeters in size utilizing either a diamond cutter or laser technology.

View Dicing Saws for sale

Assembly Process: Bonding / Completed LSI

Each IC chip pads and package terminals are connected via metal wiring and the chip is enclosed in the appropriate packaging (e.g. plastic). The LSI manufacturing process is now complete.

View Assembly Bonders for sale

Hope you have enjoyed this introduction to the semiconductor manufacturing process, brought to you by SDI Fabsurpus.com. Are you looking for used semiconductor manufacturing equipment for sale?

Look at our website: www.fabsurplus.com